In an ever-increasingly digital world, despite the advances in technologies, there seems to be a movement back toward the world of physical products. It could be the Amazon opportunities available now, the globalization that makes importing from overseas easy, or simply just the love of tangible goods.

The difference between the world of digital products and physical products is HUGE. To put it simply, for digital products the main cost is your time, for physical products there’s time as well as manufacturing, production, shipping, packaging, storage… you get the idea.

Over the past several years as I’ve started and grown several product companies, I have learned a few things about the process that I want to share with you in this article.

Today I’m going to teach you the following:

- Perceived Value; Why Physical Products win and how to use them with digital products to reduce refunds.

- How to find overseas manufacturers through Alibaba without getting ripped off.

- Cost Analysis; How to price your product while staying profitable and competitive

- Wholesale and bulk pricing; How to price accordingly

- Shipping and Fulfillment; Why you’re paying more $$$ by shipping yourself

My goal is for you to finish this post thinking “I can do that.” and then for you to email me in six months with a link to your product in a store 🙂

Physical Vs. Digital

The perceived value of something is the worth that a product or service has in the mind of the customer. This perceived value they have affects the price that he or she is willing to pay for it. In this regard, physical products always beat out digital products.

How many of you have either bought or been given a PDF or course that is “valued at $297” and you never even look at it?

I know I’m guilty.

How many of you have purchased something physical from a store for $297 but never taken it out of the box?

Probably not many, and if you did that, it probably sat there on the shelf mocking you and making you feel silly for buying something you never actually opened.

(Yes I am, on rare occasions, mocked by unopened boxes)

As you can see from these examples, there’s automatically a value placed on something physical because we can touch and feel it. It’s real. I believe it’s one of the reasons why in the year 2016 Tony Robbins sent out a physical DVD box set and books for his personal development courses. There is an experience and responsibility when you get a physical box set in the mail.

Now if you don’t complete this, it will take up space in your home as a physical reminder that you never completed it.

You’re also much less likely to return it, unlike with a digital product which you can ask for a refund on without much more hassle than sending an email.

People’s perception of value is much greater when they have something in their hands that they can hold.

I bought an online course from AppSumo in 2013, and they sent me a small Moleskine notebook in the mail about a week after receipt of the purchases. It was awesome and memorable. Of all the digital products I had ever bought they were the first to do this. It created a physical connection to an otherwise digital product.

It created a physical connection to an otherwise intangible digital product.

I would bet money that this small gesture goes a long way towards decreasing buyer remorse and refund rates as you’re creating a physical connection to a customer for an otherwise digital product.

Keys to a great product:

- Solves a pain / Fulfills a need

- A great story

- Great design (and packaging)

With Calm The Ham and now BestSelf Co, I have had my share of good and bad experiences with bringing physical products to life. While most of these have been in the printed realm (posters, prints, t-shirts, laser-cut wood, books, etc.) the necessary process from design to shipment is essentially the same.

So you have a product idea and an idea of how to make it… what now?

Step 1: Idea to Design

Years ago when you had an idea for a product, you would have to put in a lot of time and money to even get to the prototyping phase. Now with the emerging 3D printer market you’ve cut your time and cost down significantly which means it’s become easier to get a product to market than ever before.

Got an idea but am not sure of the next steps to prototype, here’re a few resources:

Sculpteo & Shapeways is an on-demand 3D printing company that is great for prototyping. Due to its cost-effectiveness, you can create multiple prototypes without too much hassle or cost with a turnaround time of only ten days.

TechShop A workshop for prototyping ($100 p/month) where you get access to 3D Printers, laser cutting machines, CNC Mills, and a woodshop. They have everything you need to get an idea from a sketch to a physical product.

The complexity of the product has a lot to do with the next steps. Depending on your area of expertise you may want to recruit the following for help:

- An engineer

- A developer

- A designer

- A Manufacturer (we’ll get to that next)

Unlike years ago when you needed to fund the initial manufacturing run yourself, which loads you with some big risks, now we have crowdfunding platforms like Indiegogo or Kickstarter that can help with this. The great thing about these is that you can launch a product with only a prototype! I recently shared with you the 7 Reasons Why You Should Crowdfund Your Idea.

Step 2: Finding a Manufacturer

Finding a good manufacturer or supplier is key to your business. Similar to finding a spouse, you probably shouldn’t jump at the first one you find.

Therefore, you should take your time to ensure you vet them thoroughly.

When finding a quality manufacturer, here’s how I like to play it:

- Find 4–5 Suppliers in the product market you’re looking for

- Ask them to send you samples of their best quality products (preferably that will be of similar grade/material to what you’re looking for)

- Pair down the best 2–3 product sample suppliers and ask for a prototype of your design (if possible)

- Choose a manufacturer based on sample quality, responsiveness, and cost.

- Make a damn great product.

Here are the three things you look for in a good manufacturer:

1. Quality

Before I start working with anyone and before I even show them what I want them to make I ask to see examples of past work they’ve done. The quality of the end product is my priority, and I can judge from samples if they have the attention to detail that I need.

Consider that whatever they send you is the best they have to offer so you see them in the best light, if the quality is mediocre, you can expect the same or less from your end product.

2. Communication

A manufacturer who takes a week to respond to you is not going to work. That’s why you need to ensure their communication is on point before you begin to work with them. Ask them every and all questions you have about the process and how it will work ahead of time.

The reason to pepper them with questions early on is to check how responsive they are and open to giving you answers when they have no skin in the game yet. Once manufacturing starts, issues can occur and you need to ensure that you can communicate effectively with them before it’s too late.

3. Cost

The reason I put the cost third on the list is that you should never start a relationship with a manufacturer by asking about cost as a starting point.

You may come off as price-sensitive which can scare them off, or even worse, and they will use low-quality materials to offer you a lower price.

Instead, start the conversation with the quality of products and materials, how they compare to competitors on quality, and what you’re looking for in a manufacturer. Once you’re happy with the answers, you can discuss the cost.

Generally, with this approach, you will get more respect as a buyer, and price negotiation is easier.

Now let’s dig into where you find manufacturers.

If you’re looking for a U.S.-based manufacturer, your best bet is Google or Maker’s Row for a directory of U.S. manufacturers.

All my Calm The Ham products are U.S.-based due to their nature. A great place to find quality printers is InkerLinker where I have sourced many great printers for letterpress, lithographic, and other great stuff.

How to Source Manufacturers through Alibaba

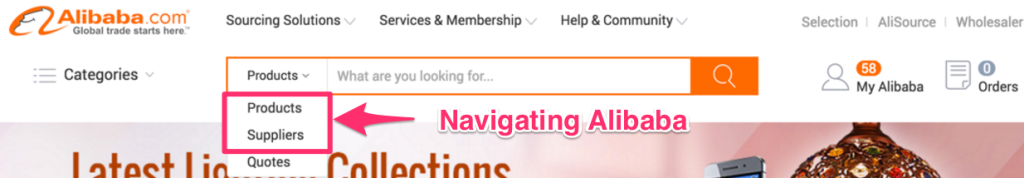

The biggest directory of overseas manufacturers and suppliers is on Alibaba, which is, in fact, the largest eCommerce company in the world and the most comprehensive list you’ll find. It’s where I have sourced the majority of my products through.

You can search the site using various filters, typically the most useful I’ve found is through Products and Suppliers:

3 Criteria when choosing a Supplier, ensure they are:

- Supplier Assessed

- Gold Supplier

- Have Trade Assurance

Meeting these criteria for choosing who you work with will save you time in the long run.

For the SELF Journal, we sourced 3–4 different manufacturers at first as we wanted to compare each factory for product quality, pricing, and responsiveness before we committed to one. We all know you don’t marry your manufacturer on the first date (or your first 1 am Skype conversation.)

That’s another thing, you need to be available to speak to them in their time, being in New York, meant staying up late or getting up early. Hello, 5 am!

What You Should Know

There’s some lingo when you start working with manufacturer’s that you need to know, here’re the big things:

Minimum Order Quantity

The MOQ is the minimum number of units that the manufacturer will allow per order. Usually, this is done for cost purposes, and it’s much more expensive to create 100 of something than 10,000. Most listings include MOQ. However, you want to double-check with them on this first.

As a general rule, as the quantity of units goes up, the price per unit will go down. Therefore, you will need to account for this in your initial costs. I like to ask the manufacturer ahead of time for the MOQ and higher quantity prices to get an idea of what the pricing quantity breaks are.

For example for the SELF Journal, I asked for pricing based on:

- 2,500 units

- 5,000 units

- 10,000 units

Payment Terms

If you are brand new to Alibaba (and business), chances are you will need to front the entire costs upfront to your manufacturer. Commonly they take a percentage up front and the rest before they ship. However, you’re likely not going to get credit until you work with them a few times.

For the SELF Journal, we paid a 20% deposit upfront, 30% after printing, 30% after binding and the last 20% before shipping. This meant we paid the entire upfront amount over 6–8 weeks, sent via wire transfer.

Lead/Production Time

Ask how long between the approval of the sample and final production as you will need to know this to be able to guess how long the process will take and when you can reasonably expect to deliver to customers.

Samples

Paying for samples can vary from one supplier to the next. At a minimum you will have to cover the shipping costs from the supplier to you, often if you do this, they will send a sample free of charge. However, it’s in their discretion to charge you if they want… so be nice! Once you build up a rapport and a relationship with a supplier they will often waive fees for small charges like this.

Prototyping

Get a prototype made of your design before going into to final product. It may cost you but it’s worth it. The last thing you want to do is to go into mass production on a flawed product.

For the SELF Journal, we paid for three prototypes from 3 different companies before we moved forward with the final supplier we ended up going with. The price per journal was between $120 – $150 per journal for the one-off print. They also did not come with all the bells and whistles due to it being a one-off. However, we knew they were capable of doing what we needed from the previous samples they’d sent.

Pricing

Now you know how to find a supplier, and you need to figure out how to price your product. When we are beginning with physical products, pricing can be a little tricky due to all the individual costs involved. The key to pricing for physical products is:

- Knowing all your costs inc labor, packaging, production, shipping, fees, etc

- What is the minimum unit quantity for the order

- Review competitor pricing for an overall view of what consumers will pay

When you get the cost per unit, you need to factor in shipping to the U.S. which can get pricey depending on quantity, weight, etc. Our freight shipping costs and trucking to our warehouse were over $10,000. However, this was for 25,000 units which worked out at only 40 cents extra per unit.

Raw cost per unit = Manufactured cost per unit + Shipping cost/# of units

Wholesale Pricing

Another important aspect to consider for pricing is if you’re planning on selling with external retailers you will need to ensure your margins can withstand the 40–50% standard wholesale discount pricing.

Think it’s a steep discount? Consider the incurred cost of running a store, the rent, the maintenance, and the staff. They need to make money off your products, or they are useless to them. Therefore, this discount is an average across the wholesale industry.

Bulk Pricing

Bulk pricing works a little differently than wholesale while these customers will also order in quantity, they are not trying to make up their retail margins. Therefore, I don’t offer this same standard wholesale pricing.

For bulk pricing for BestSelf, we offer quantity price breaks based on how many units they want to buy. Someone buying 100 of a product will get a better deal than someone buying 15.

Shipping & Fulfillment

When bootstrapping you often follow this path at the beginning: Ship yourself ➨ Pay someone else to ship ➨ Outsource shipping completely

When I first started selling physical products online, I would do everything myself. The design, production, sales, marketing, shipments. In the beginning, shipping was easy because I had so few sales.

At the time, I was still working at my architecture job and would bring orders to the post office before work or during my lunch break. Sometimes on the weekends, I would even bring my dog:

However once I started doing any volume it got tricky, and that process would not scale, so I pivoted. During the Christmas rush, I would pay a TaskRabbit to come to my apartment, pick up my bags of orders, and deliver them to the post office for me.

Also not scalable, but a measurable improvement.

Later after I quit my job, during the busy season, I would pay someone $10 an hour to come to my apartment and pack orders for me.

Then I found myself a fulfillment center. The holy grail.

By shipping myself, in the beginning, I knew exactly how fulfillment needed to go and what the requirements were per order which meant creating a system for them to follow was pretty easy. This is where creating systems and processes comes in handy.

Fulfillment

Fulfillment centers can vary from one style to the next, for example, Amazon FBA wants your products pre-packaged and labeled so they can place it in a box and send it out. No muss no fuss.

However, for my Calm The Ham business I needed something more custom due to the nature of the goods. Most customers often buy more than one print at a time, which can be sent in one single tube.

In the case of Amazon FBA, if each print were in pre-packed tubes, it would have meant someone receiving multiple tubes rather than one which would mean increased shipping and material costs.

If you have a situation where you need something more custom like I did, a good way to figure out how to handle this for yourself (if you’re not sure what to do) is to look at what other people are doing.

- Find companies that sell similar products

- Email and ask them how they handle fulfillment (abundant entrepreneurs will likely share).

- If that doesn’t work, order from them and see what the return address is and how it’s packaged. You’ll be able to tell quickly whether it’s a fulfillment center or not.

Why you’re throwing away money by shipping yourself

(I say this for the solopreneurs like me or small businesses with very limited staff)

When shipping yourself, you’re doing a very low-leverage job that you could be paying someone else to do it for little money. This frees you up for more important tasks like growing your business and creating more products.

You as a business owner should be focused on revenue-generating activities, of which shipping orders are not one.

Still think you’ll do it yourself? How about if I shared with you that it costs you more money to ship yourself?

Here’s how…In 2013, I did EVERYTHING myself, and because I was using my time for this, my profits at the end of the year were larger. What does this mean?

I paid a crap-load more in taxes. Happy IRS… Sad me.

In 2014, I got a fulfillment center on board to ship out all of my orders. I built systems and a virtual team in the business so that it could run without me. This meant my apartment was my own again (not a shipping warehouse).

Once again I had the freedom to travel and even more compelling, I paid much less in taxes despite having made more revenue.

Higher revenue but w/ more business expenses = Pay Less tax Lower revenue but w/ less business expenses and spending YOUR time = Pay More Tax

Crazy right? When you are figuring out your pricing and shipment opportunities, don’t forget to factor in these opportunity costs.

I save my best stuff for my emails. No spam ever.